Western Trails Museum

Knott's Berry Farm

AMAZON FINDSAD

Snoopy T-Shirts Snoopy Stuffed Animals Knott's Raspberry Cookies

As an Amazon Associate we earn from qualifying purchases

Amusement Park Essentials

Snoopy T-Shirts Snoopy Stuffed Animals Knott's Raspberry Cookies

As an Amazon Associate we earn from qualifying purchases

Updated: October 2024

Posted: March 2022

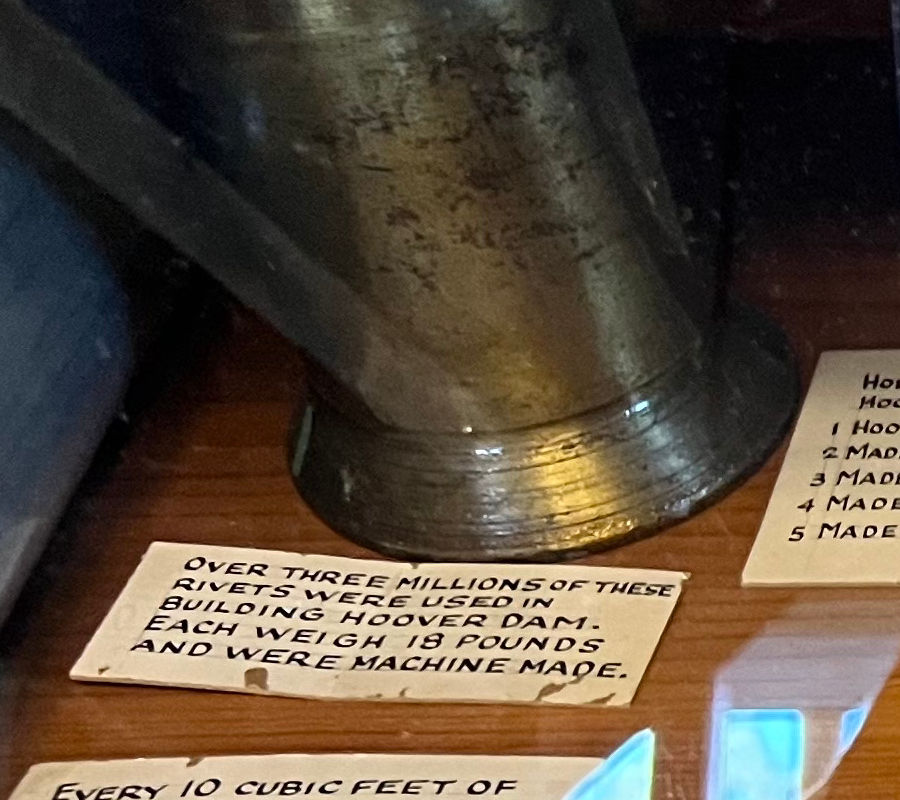

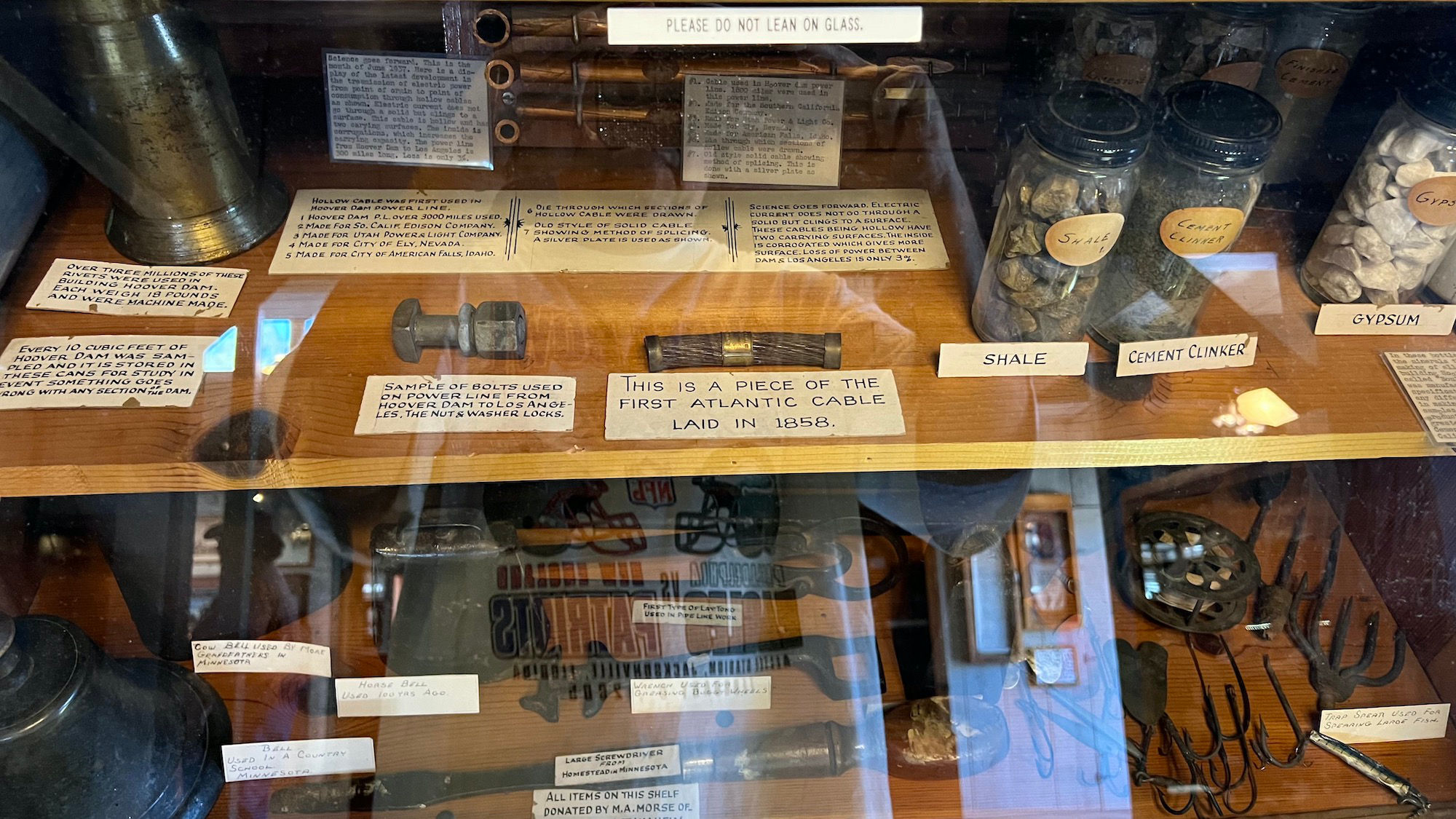

Hoover Dam Items

- Over three million of these rivets were used in building Hoover Dam. Each weigh 18 pounds and were machine made

- Every 10 cubic feet of Hoover Dam was sample and it is stored in these cans for study in event something goes wrong with any section of the dam.

- Science goes forward. This is the month of June 1937. Here is a display of the latest development in the transmission of electric power from point of origin to point of consumption through hollow cables as shown. Electric current does not go through a solid but clings to a surface. This cable is hollow and has two carrying surfaces. The inside is corrugations, which increases the carrying capacity. The power line from Hoover Dam to Los Angeles is 300 miles long. Loss is only 3%.

- Hollow cable was first used in Hoover Dam power line.

- Hoover Dam PL over 3000 miles used.

- Made for Southern California Edison Company.

- Made for Utah Power & Light Company.

- Made for City of Ely, Nevada.

- Made for City of American Falls, Idaho.

- Dia through which sections of hollow cable were drawn.

- Old style of solid cable showing method of splicing. A silver plate is used as shown.

- Cable used in Hoover Dam power line. 1800 miles were used in this power line.

- Made for the Southern California Edison Company.

- Made for Utah Power & Light Company.

- Made for City of Ely, Nevada.

- Made for City of American Falls, Idaho.

- Dia through which sections of hollow cable were drawn.

- Old style of solid cable showing method of splicing. This is done with a silver plate is used as shown.

- Sample of bolts used on power line form Hoover Dam to Los Angeles. The nut & washer locks.

- This is a piece of the first Atlantic Cable laid in 1858.

- Shale

- Cement Clinker

- Gypsum