Car manufacturer Chrysler built 60,000 guns and 120,000 barrels, after translating the instructions from Swedish and converting measurements from metric. The gun weighed 1037 pounds, 149 inches long, and was air-cooled. Gun crews were generally made up of five or six men. They could fire an average of 80 to 90 rounds per minute.

Anti-Aircraft Defense

When WWI broke out in 1914, air power was in its infancy, but by 1918, it grew to be a force to be reckoned with. In the beginning, most air operations consisted of reconnaissance missions: monitoring troop movements, photographing defenses, and making maps. That soon transitioned into actual aerial combat, both aircraft against aircraft and aircraft attacks on ground forces. This necessitated a ground defense against incoming planes.

The first dedicated anti-aircraft gun, the 3" M1917, developed in 1915 and entered into service in 1917. The M1917 was superseded by the M1918, and then the M3 in 1930. In the years leading up to WWII, the Army developed larger and more powerful guns as well as mobile anti aircraft guns.

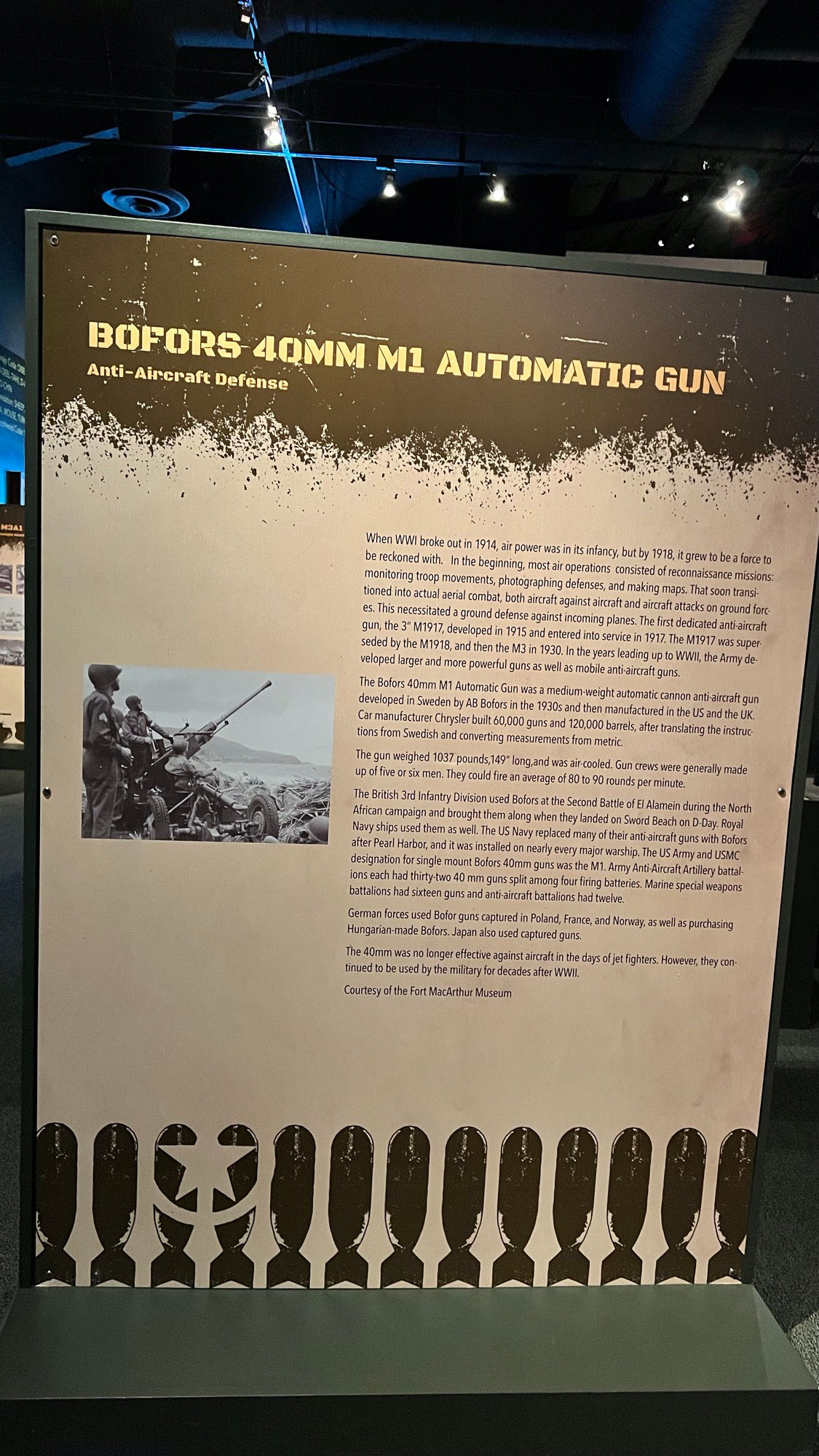

The Bofors 40mm M1 Automatic Gun was a medium-weight automatic cannon anti-aircraft gun developed in Sweden by AB Bofors in the 1930s and then manufactured in the US and the UK. Car manufacturer Chrysler built 60,000 guns and 120,000 barrels, after translating the instructions from Swedish and converting measurements from metric.

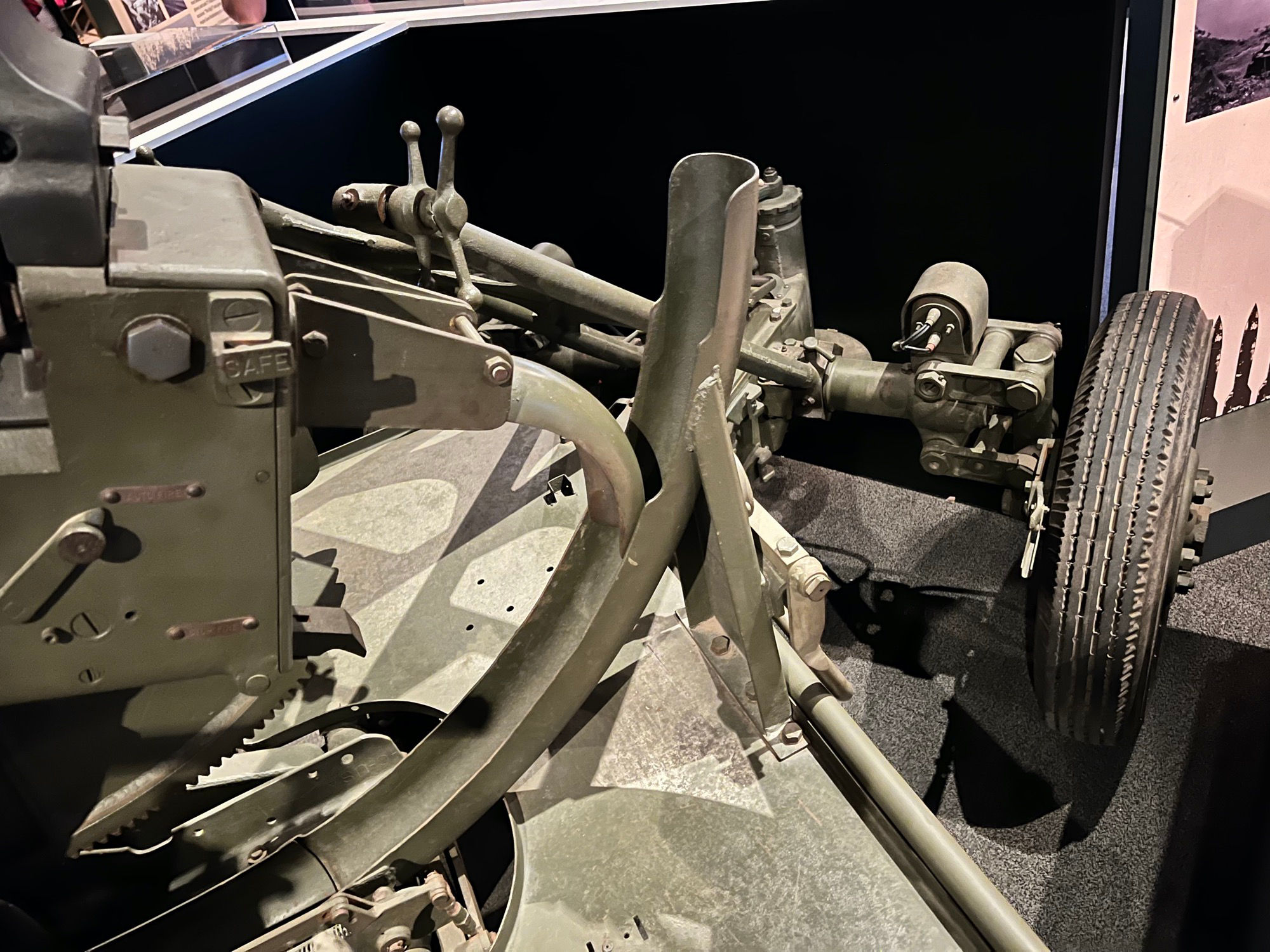

The gun weighed 1037 pounds, 149" long, and was air-cooled. Gun crews were generally made up of five or six men. They could fire an average of 80 to 90 rounds per minute.

The British 3rd Infantry Division used Bofors at the Second Battle of El Alamein during the North African campaign and brought them along when they landed on Sword Beach on D-Day. Royal Navy ships used them as well. The US Navy replaced many of their anti-aircraft guns with Bofors after Pearl Harbor, and it was installed on nearly every major warship.

The US Army and USMC designation for single mount Bofors 40mm guns was the M1. Army Anti-Aircraft Artillery battalions each had thirty-two 40 mm guns split among four firing batteries. Marine special weapons battalions had sixteen guns and anti-aircraft battalions had twelve.

German forces used Bofor guns captured in Poland, France, and Norway, as well as purchasing Hungarian-made Bofors. Japan also used captured guns.

The 40mm was no longer effective against aircraft in the days of jet fighters. However, they continued to be used by the military for decades after WWII.

WIKIPEDIAThe Bofors 40 mm Automatic Gun L/60

The Bofors Gun

It's an anti-aircraft autocannon, designed in the 1930s by the Swedish arms manufacturer AB Bofors. The gun was designed as an intermediate anti-aircraft gun, filling the gap between fast firing close-range small calibre anti-aircraft guns and slower firing long-range high calibre anti-aircraft guns, a role which previously was filled by older outdated guns. The Bofors 40 mm L/60 was for its time perfectly suited for this role and outperformed competing designs in the years leading up to World War II in both effectiveness and reliability.It entered the export market around 1932 and was in service with 18 countries by 1939. Throughout World War II it became one of the most popular and widespread medium-weight anti-aircraft guns. It was used by the majority of the western Allies and some Axis powers such as Nazi Germany and Hungary.

Contrary to the name, the Bofors 40 mm Automatic Gun L/60 has an actual barrel length of 56.25 calibres – 7 ft 5 in.

US Manufacturing

In order to supply both the U.S. Army and U.S. Navy with much greater numbers of the guns, Chrysler built 60,000 of the guns and 120,000 barrels through the war. Over the lifetime of the production, their engineers introduced numerous changes to improve mass production, eventually halving the overall time needed to build a gun. Most of the changes were in production methods rather than the design of the gun itself: for example, milling from steel block was replaced by stampings and castings whenever possible.There were many difficulties in producing the guns within the United States, beyond their complexity (2,000 subcontractors in 330 cities and 12 Chrysler factories were used to make and assemble the parts). The drawings were metric, in Swedish, with loose tolerances for hand fitting and read from the first angle of projection. Chrysler had to translate to imperial measures and English language, fix absolute dimensions, and mirror/reorder the drawings to the third angle of projection.

Swedish blueprints had many notes on them such as "file to fit at assembly" and "drill to fit at assembly," all of which took much production time in order to implement. Thirdly, the Swedish mountings were manually worked, while the USN required power-worked mountings in order to attain the fast elevation and training speeds necessary to engage modern aircraft. Fourthly, the Swedish guns were air-cooled, limiting their ability to fire long bursts, a necessity for most naval AA engagements. Finally, the USN rejected the Swedish ammunition design, as it was not boresafe, the fuze was found to be too sensitive for normal shipboard use and its overall design was determined to be unsuitable for mass production.